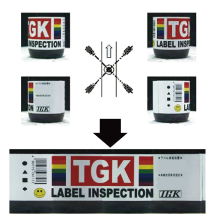

Label inspection system that inspects bottle products by reconstructing multiple camera view images into one single label image.

複数のカメラ画像を1つの画像にして検査するラベル検査装置

We have developed the system employing our unique technology which automatically detects such defects as minute label break, stain, printing failure, etc. by taking images of the appearance of labeled bottle products (glass bottles, cans, PET bottles, etc.) with multiple industrial video cameras. We provide this system to major beverage manufacturers in Japan. We also manufacture inspection system which can take in inner/outer information of products through capturing images by utilizing X-ray, visible light, near infrared rays, etc. and then can process these data at high-speed, which enables the applicable automated inspection in production line.

ラベルが貼られたボトル製品(びん、缶、PETボトル)等の外観を複数のカメラで撮像し、当社の独自技術により、小さな破れ、汚れ、印刷不良などの欠陥を自動検出する装置を開発し、国内大手の飲料メーカーに供給しています。また、当社はX線、可視光、近赤外線などを駆使し、対象物の内部・外部情報を画像で取り込み、そのデータを高速で処理し、生産ラインで使用できる検査装置を製造しています。

Development, manufacturing, and installation of various non-destructive inspection system and material discrimination system such as label inspection system, X-ray fill level inspection system, printing inspection system, filled bottles foreign object inspection system, X-ray foreign object inspection system, X-ray fill level and cap tightening inspection system, filled bottles appearance inspection system, cap appearance inspection system, X-ray imaging measuring system, material discrimination system using near infrared ray, X-ray lumber inner-defect inspection system, lumber appearance inspection system and so on.

非破壊検査装置・素材分類処理装置の開発、製造、据付工事、ラベル検査装置、X線入味検査装置、印刷検査装置、実瓶異物検査システム、X線異物検査装置、X線入味・キャップ締付検査装置、実瓶外観検査装置、キャップ外観検査装置、X線撮像測定装置、近赤外線材質分類装置、木材用X線検査装置、木材外観検査装置など自動車用自動変速機(AT)部品の開発、製造など